Hydrogen Application

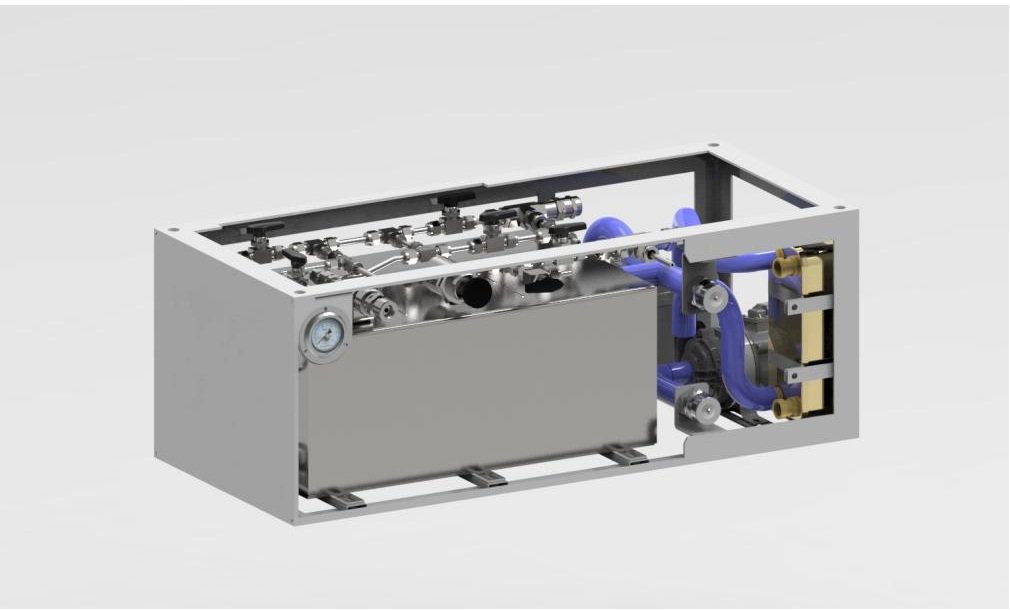

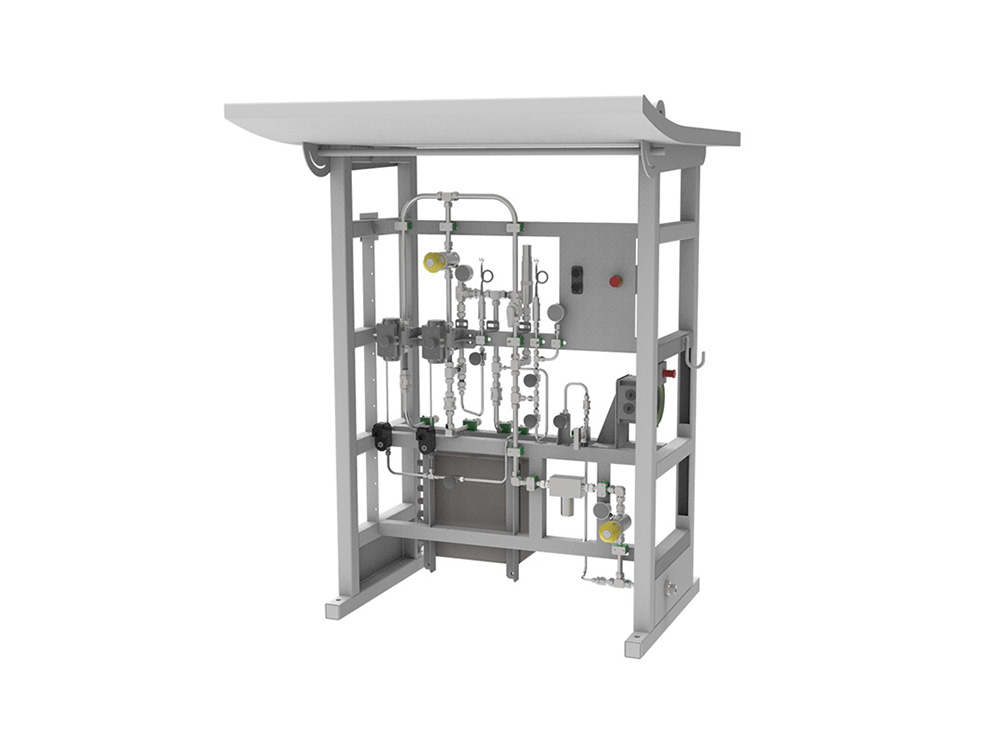

Priority Panel

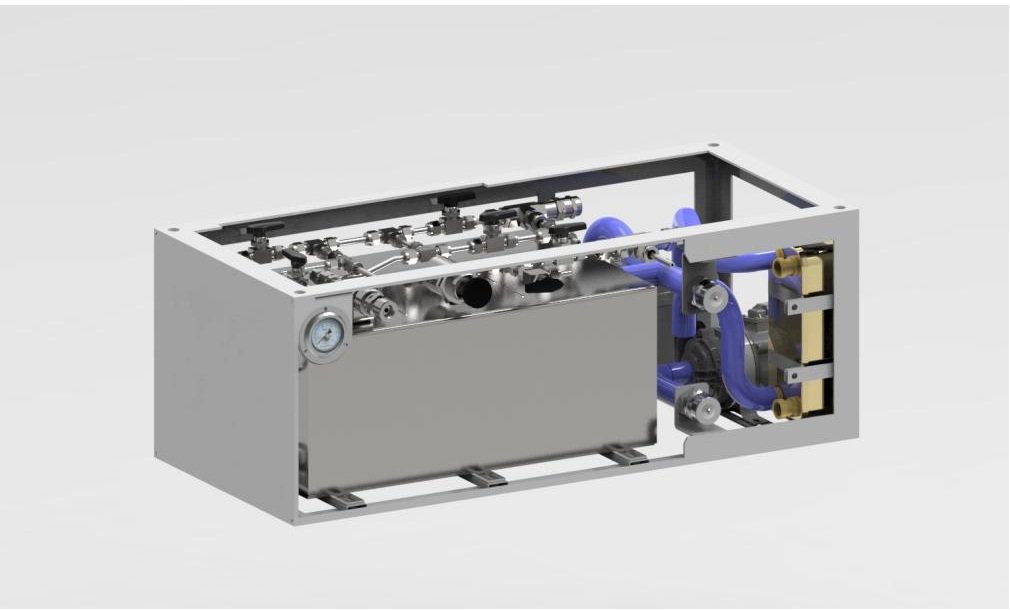

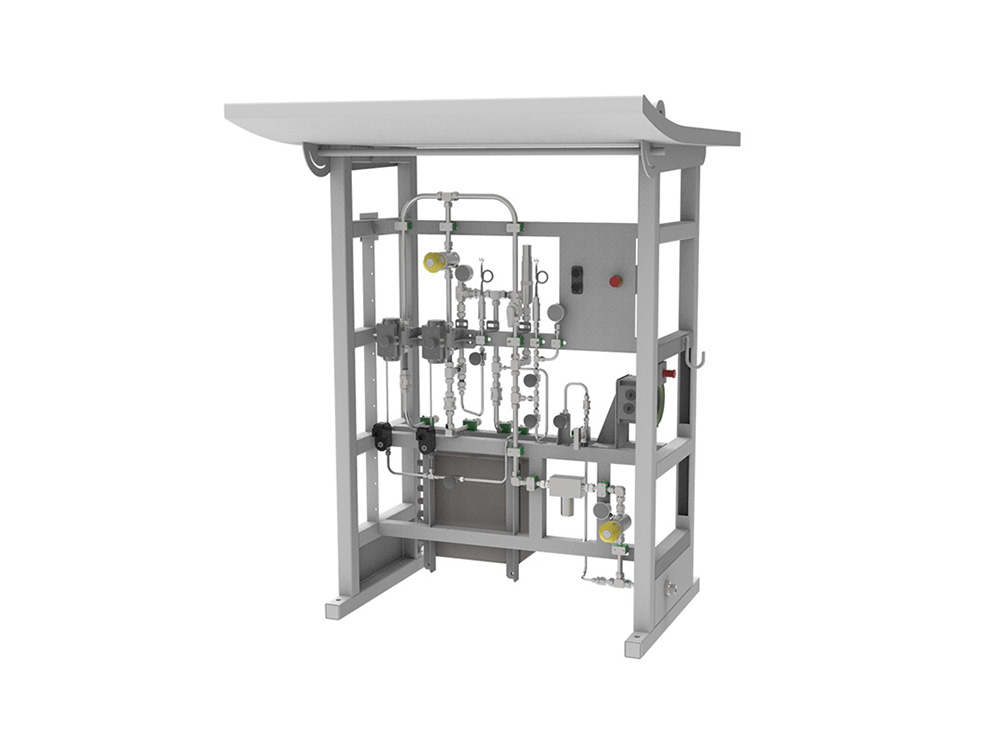

The priority control panel is an automated control device utilized in hydrogen refueling stations for the filling of hydrogen storage cascades and hydrogen dispensers. It is available in two configurations: a two-way cascade system with high and medium-pressure banks, and a three-way cascade system with high, medium, and low-pressure banks, designed to meet the diverse cascade filling requirements of hydrogen refueling stations.

As the core control element of the entire system, it automatically regulates hydrogen flow direction through programming set by the control cabinet. The priority panel primarily consists of control valves, safety venting devices, electrical control systems, and other components, featuring intelligent cascade filling, rapid filling, low-consumption direct filling (tube trailer filling mode), and pressure-boosted direct filling (compressor direct filling) capabilities.

The priority control panel is an automated control device utilized in hydrogen refueling stations for the filling of hydrogen storage cascades and hydrogen dispensers. It is available in two configurations: a two-way cascade system with high and medium-pressure banks, and a three-way cascade system with high, medium, and low-pressure banks, designed to meet the diverse cascade filling requirements of hydrogen refueling stations.

As the core control element of the entire system, it automatically regulates hydrogen flow direction through programming set by the control cabinet. The priority panel primarily consists of control valves, safety venting devices, electrical control systems, and other components, featuring intelligent cascade filling, rapid filling, low-consumption direct filling (tube trailer filling mode), and pressure-boosted direct filling (compressor direct filling) capabilities.

Product Features

● Equipped with a manual vent valve for convenient on-site maintenance or replacement

● Automatically fills storage cascades or hydrogen dispensers without manual intervention

● Capable of direct filling from tube trailers to station storage cascades and hydrogen dispensers

● Customizable according to specific customer requirements

● All explosion-proof electrical components are suitable for hydrogen environments

● Integrated safety monitoring and alarm systems for enhanced operational safety

● User-friendly interface for easy operation and monitoring

Application Scenario

The priority control panel is primarily employed in hydrogen refueling stations and hydrogen production mother stations. Hydrogen pressurized by the compressor is stored in different pressure banks within the station's hydrogen storage system. When vehicle refueling is required, the electronic control system automatically selects low, medium, or high-pressure hydrogen based on storage pressure levels. The direct filling function can be customized according to specific customer requirements, providing operational flexibility and efficiency.

This system ensures optimal utilization of stored hydrogen while maintaining safe operating pressures and efficient refueling cycles, making it an essential component for modern hydrogen refueling infrastructure.

Product Features

● Equipped with a manual vent valve for convenient on-site maintenance or replacement

● Automatically fills storage cascades or hydrogen dispensers without manual intervention

● Capable of direct filling from tube trailers to station storage cascades and hydrogen dispensers

● Customizable according to specific customer requirements

● All explosion-proof electrical components are suitable for hydrogen environments

● Integrated safety monitoring and alarm systems for enhanced operational safety

● User-friendly interface for easy operation and monitoring

Application Scenario

The priority control panel is primarily employed in hydrogen refueling stations and hydrogen production mother stations. Hydrogen pressurized by the compressor is stored in different pressure banks within the station's hydrogen storage system. When vehicle refueling is required, the electronic control system automatically selects low, medium, or high-pressure hydrogen based on storage pressure levels. The direct filling function can be customized according to specific customer requirements, providing operational flexibility and efficiency.

This system ensures optimal utilization of stored hydrogen while maintaining safe operating pressures and efficient refueling cycles, making it an essential component for modern hydrogen refueling infrastructure.

On-board Integrated Hydrogen Storage and Supply System-

On-board Integrated Hydrogen Storage and Supply System

On-board Integrated Hydrogen Storage and Supply System The On-board Hydrogen Storage and Supply System is specifically designed to meet the application requirements of hydrogen fuel cell vehicles such as sightseeing vehicles, forklifts, and other mat...

Energy-storage-grade Metal Hydride Hydrogen Storage and Supply System-

Energy-storage-grade Metal Hydride Hydrogen Storage and Supply System

High-Density, Safe Hydrogen Storage Solution This system utilizes high-performance hydrogen storage alloy as the hydrogen storage medium and adopts a modular structure design. We can customize and develop various metal hydride hydrogen storage device...

Small Mobile Metal Hydride Hydrogen Storage Cylinder-

Small Mobile Metal Hydride Hydrogen Storage Cylinder

Portable, Safe Hydrogen Storage Solution Utilizing high-performance hydrogen storage alloy as the hydrogen storage medium, this product can reversibly absorb and release hydrogen at specific temperature and pressure conditions. It is widely applicabl...

Hydrogen Loading/Unloading Post-

Hydrogen Loading/Unloading Post

The hydrogen loading/unloading post integrates an electrical control system, mass flow meter, emergency shut-off valve, breakaway coupling, and associated piping and valves. This system is designed to intelligently complete gas accumulation metering ...

Containerized High Pressure Hydrogen Refueling Equipment-

Containerized High Pressure Hydrogen Refueling Equipment

The containerized high pressure hydrogen refueling equipment, serving as the core component of the hydrogen refueling station, is an integrated system primarily consisting of hydrogen compressor, pipeline system, cooling system, and electrical contro...

Two Nozzles and Two Flowmeters Hydrogen Dispenser-

Two Nozzles and Two Flowmeters Hydrogen Dispenser

Advanced Hydrogen Refueling Solution for Fuel Cell Vehicles The hydrogen dispenser is a specialized device that enables safe and efficient refueling for hydrogen-powered vehicles, intelligently completing gas accumulation measurement. It is primarily...

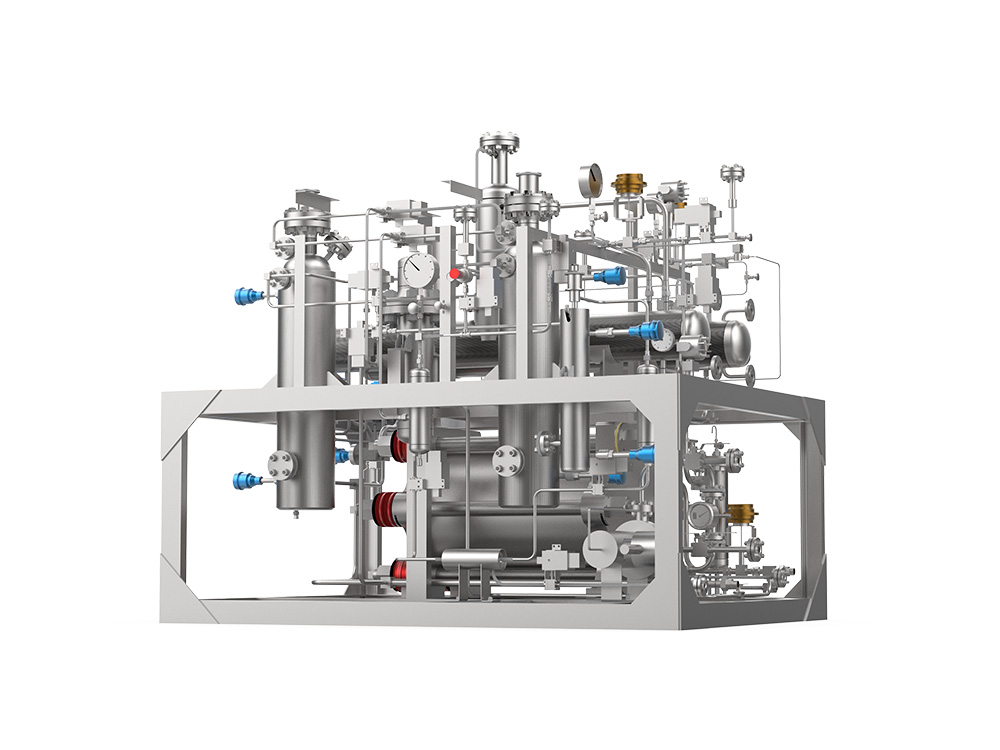

Hydrogen Diaphragm Compressor-

Hydrogen Diaphragm Compressor

Hydrogen diaphragm compressor is divided into two series of medium pressure and low pressure, which is the booster system at the core of the hydrogenation station. The skid is composed of hydrogen diaphragm compressor, piping system, cooling system a...

Liquid-driven Hydrogen Compressor-

Liquid-driven Hydrogen Compressor

Hydrogen compressors are mainly used in HRS. They boost low-pressure hydrogen to a certain pressure level for hydrogen storage containers on site or for direct filling into vehicle gas cylinders, according to customers’ hydrogen refueling needs.

High-Pressure Gas Storage tank-

High-Pressure Gas Storage tank

We utilize high-quality materials (4130X and ASME SA372 Gr.J.CI.70) and advanced seamless manufacturing processes to ensure each cylinder demonstrates exceptional structural integrity and long-term durability. Through rigorous quality control process...

Integrated Hydrogen Production and Refueling Station-

Integrated Hydrogen Production and Refueling Station

The Integrated Hydrogen Production and Refueling Station is an innovative system that combines hydrogen generation, purification, compression, storage, and dispensing functions into a single, compact unit. This integrated approach revolutionizes the ...

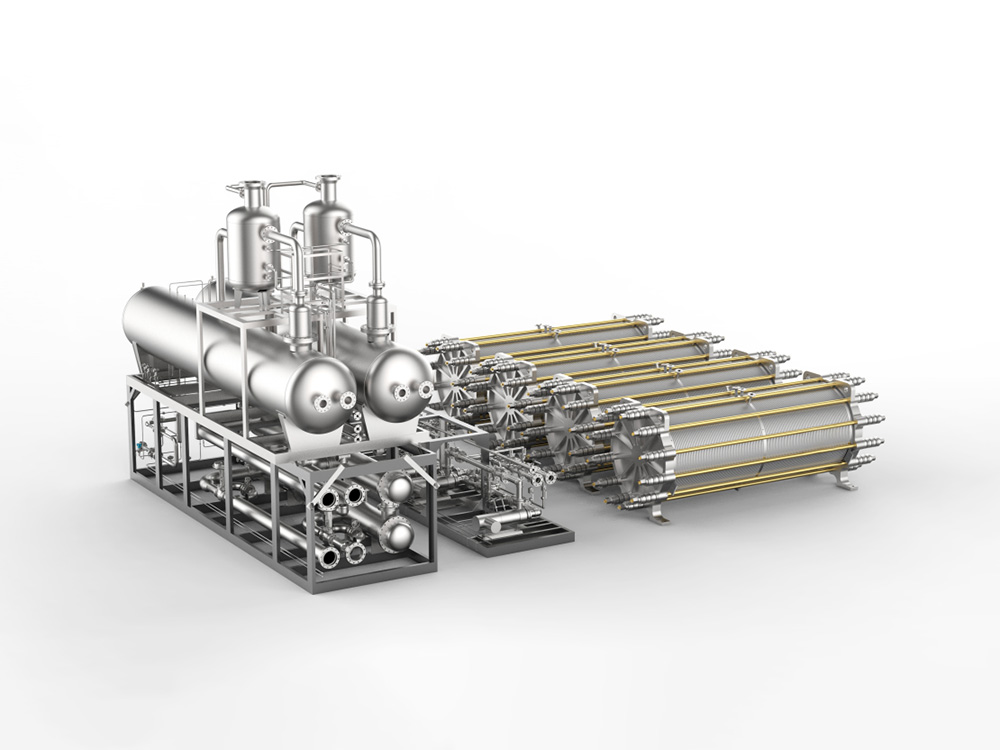

Modular Alkaline Water Electrolysis Hydrogen Production Equipment-

Modular Alkaline Water Electrolysis Hydrogen Production Equipment

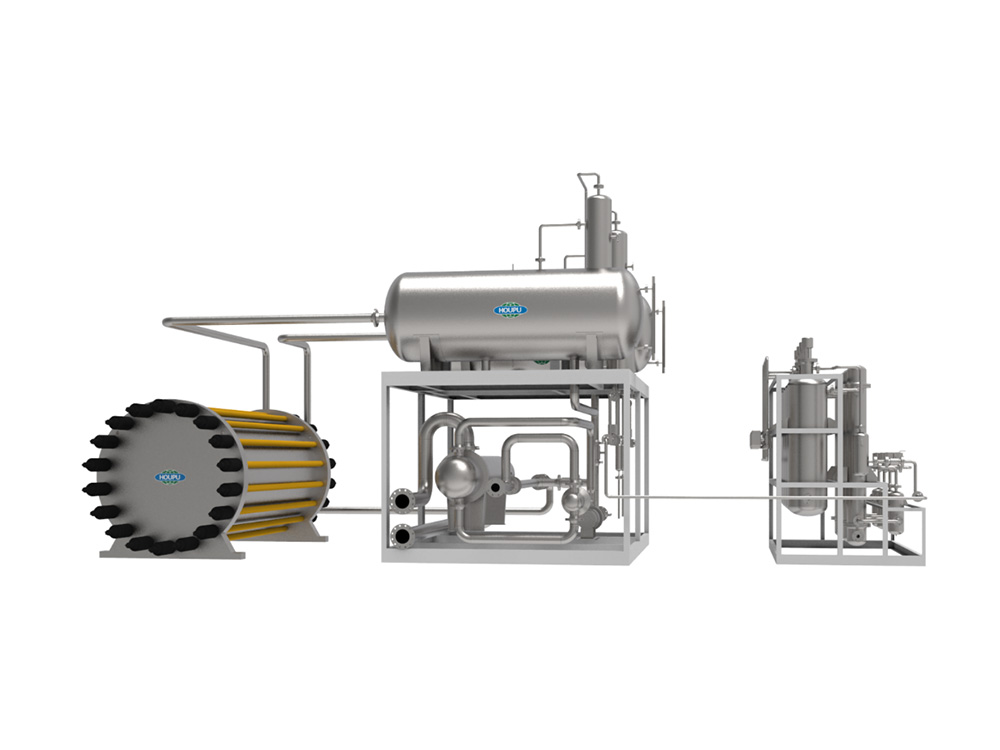

Alkaline Water Electrolysis Hydrogen Production Equipment-

Alkaline Water Electrolysis Hydrogen Production Equipment

Our alkaline electrolyzers utilize advanced electrode materials and optimized cell design to achieve superior performance metrics. The robust construction ensures reliable operation under varying load conditions while maintaining exceptional energy e...

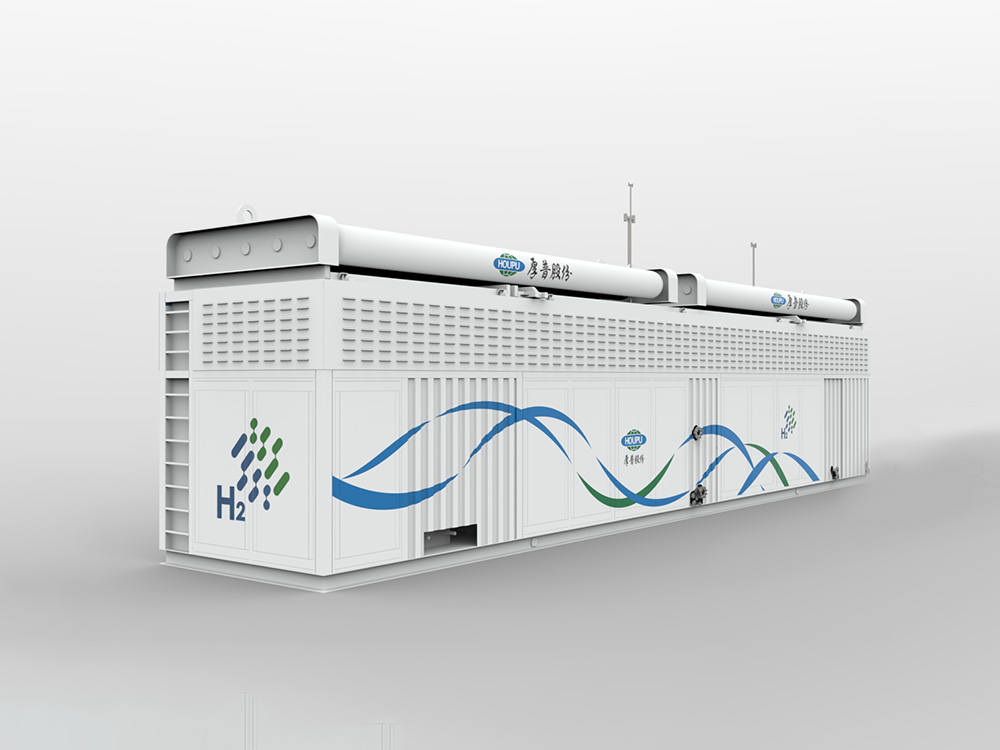

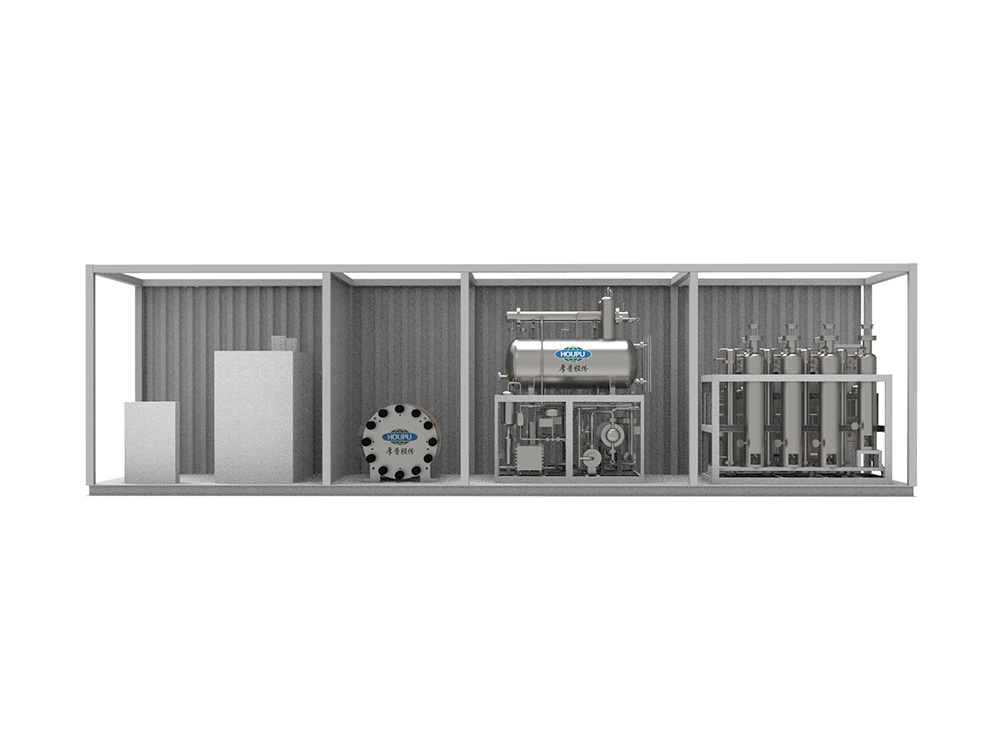

Containerized Alkaline Water Electrolysis Hydrogen Production Equipment-

Containerized Alkaline Water Electrolysis Hydrogen Production Equipment

Alkaline water electrolysis hydrogen production equipment is a complete system primarily composed of an electrolysis unit, gas separation unit, hydrogen purification unit, power supply unit, and alkali circulation unit. The containerized design offer...

Standard Alkaline Water Electrolysis Hydrogen Generator-

Standard Alkaline Water Electrolysis Hydrogen Generator

High-Efficiency Hydrogen Production Solution Our Standard Alkaline Water Electrolysis Hydrogen Generator utilizes proven, mature technology to produce high-purity hydrogen in an efficient, reliable, and cost-effective manner. Designed for large-scale...

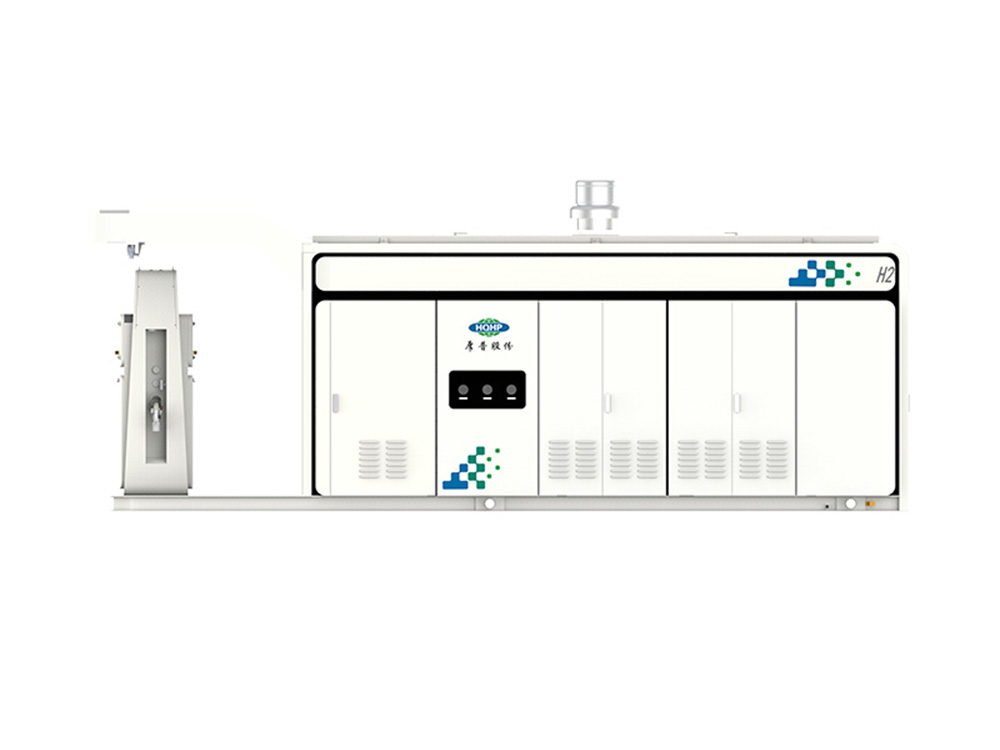

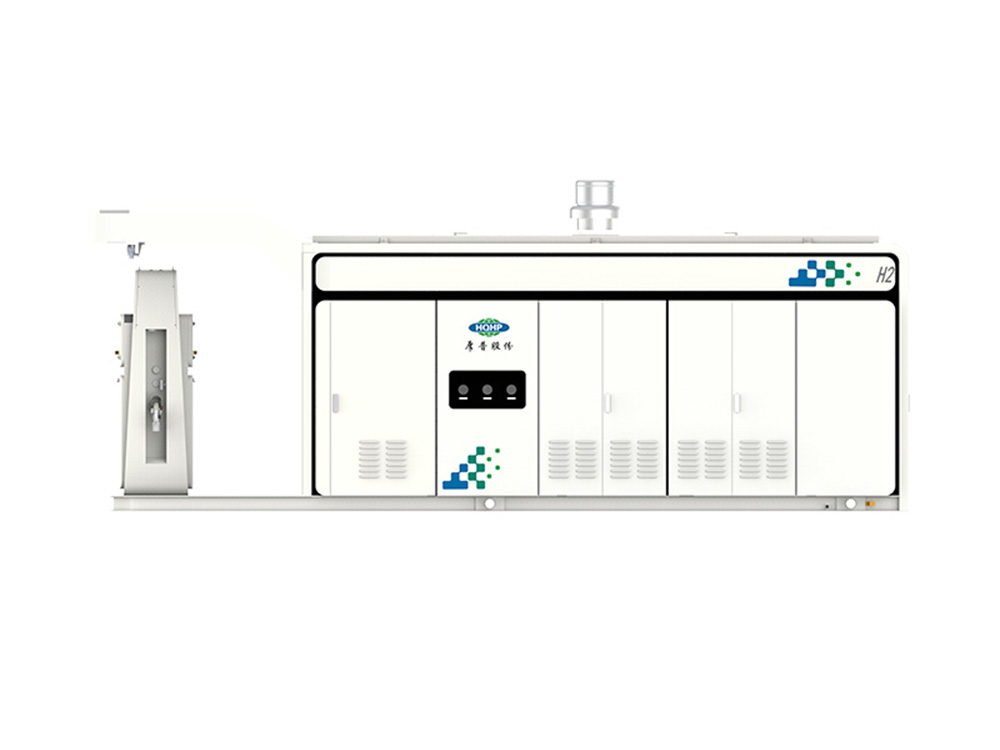

E-Series Export-Model Hydrogen Refueling Station-

E-Series Export-Model Hydrogen Refueling Station

The E series products are designed in accordance with European standards and are suitable for various demands of hydrogen refueling stations in Europe and Asia. The products come in two pressure ratings: 35 MPa and 70 MPa.

S-Series Standard Hydrogen Refueling Station-

S-Series Standard Hydrogen Refueling Station

The S series standard model products employ a modular design concept, making them suitable for customers with limited space requirements but high demands for functionality, safety protection, and automation levels.

C-Series General-Purpose Hydrogen Refueling Station-

C-Series General-Purpose Hydrogen Refueling Station

The C series universal integrated skid combines the hydrogen compressor, hydrogen refueling station, and heat exchange system into a single, compact unit. This integrated design facilitates installation, conserves project space, reduces on-site insta...

Hydrogen Energy Storage Power Generation System-

Hydrogen Energy Storage Power Generation System

Modular, Scalable Clean Energy Solution The Hydrogen Energy Storage Power Generation System adopts a skid-mounted and quick-connect design, ensuring convenient transportation and rapid deployment. This integrated system combines a solid-state hydroge...

Integrated Skid-Mounted Hydrogen Storage System-

Integrated Skid-Mounted Hydrogen Storage System

Modular, Safe and Efficient Hydrogen Storage Solution This system employs an integrated skid-mounted design that incorporates a hydrogen storage and supply module, heat exchange module, and control module. It integrates a hydrogen storage system with...

Standard Cylinder Filling System-

Standard Cylinder Filling System

Efficient and Safe Hydrogen Cylinder Filling Solution The Standard Cylinder Hydrogen Filling System is designed to meet the requirements for small-scale hydrogen storage and rapid batch filling of cylinders. This specialized equipment is used for fil...

On-board Integrated Hydrogen Storage and Supply System-

On-board Integrated Hydrogen Storage and Supply System

On-board Integrated Hydrogen Storage and Supply System The On-board Hydrogen Storage and Supply System is specifically designed to meet the application requirements of hydrogen fuel cell vehicles such as sightseeing vehicles, forklifts, and other mat...

Energy-storage-grade Metal Hydride Hydrogen Storage and Supply System-

Energy-storage-grade Metal Hydride Hydrogen Storage and Supply System

High-Density, Safe Hydrogen Storage Solution This system utilizes high-performance hydrogen storage alloy as the hydrogen storage medium and adopts a modular structure design. We can customize and develop various metal hydride hydrogen storage device...

Small Mobile Metal Hydride Hydrogen Storage Cylinder-

Small Mobile Metal Hydride Hydrogen Storage Cylinder

Portable, Safe Hydrogen Storage Solution Utilizing high-performance hydrogen storage alloy as the hydrogen storage medium, this product can reversibly absorb and release hydrogen at specific temperature and pressure conditions. It is widely applicabl...

Hydrogen Loading/Unloading Post-

Hydrogen Loading/Unloading Post

The hydrogen loading/unloading post integrates an electrical control system, mass flow meter, emergency shut-off valve, breakaway coupling, and associated piping and valves. This system is designed to intelligently complete gas accumulation metering ...

Containerized High Pressure Hydrogen Refueling Equipment-

Containerized High Pressure Hydrogen Refueling Equipment

The containerized high pressure hydrogen refueling equipment, serving as the core component of the hydrogen refueling station, is an integrated system primarily consisting of hydrogen compressor, pipeline system, cooling system, and electrical contro...

Two Nozzles and Two Flowmeters Hydrogen Dispenser-

Two Nozzles and Two Flowmeters Hydrogen Dispenser

Advanced Hydrogen Refueling Solution for Fuel Cell Vehicles The hydrogen dispenser is a specialized device that enables safe and efficient refueling for hydrogen-powered vehicles, intelligently completing gas accumulation measurement. It is primarily...

Hydrogen Diaphragm Compressor-

Hydrogen Diaphragm Compressor

Hydrogen diaphragm compressor is divided into two series of medium pressure and low pressure, which is the booster system at the core of the hydrogenation station. The skid is composed of hydrogen diaphragm compressor, piping system, cooling system a...

Liquid-driven Hydrogen Compressor-

Liquid-driven Hydrogen Compressor

Hydrogen compressors are mainly used in HRS. They boost low-pressure hydrogen to a certain pressure level for hydrogen storage containers on site or for direct filling into vehicle gas cylinders, according to customers’ hydrogen refueling needs.