Marine Application

Marine Glycol Heating Equipment

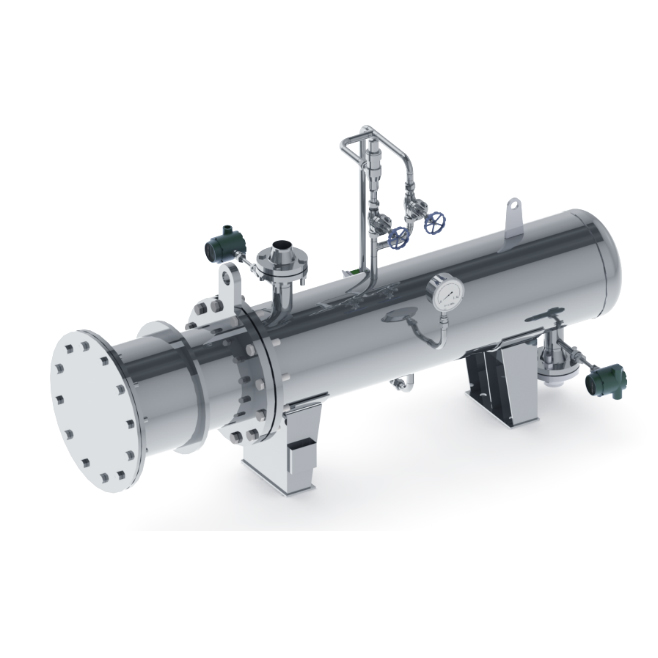

The Marine Glycol Heating Equipment is a specialized thermal management system designed for marine applications, particularly in LNG-powered vessels. This equipment efficiently heats glycol-water mixture to provide reliable thermal energy for various shipboard systems.

The system primarily consists of centrifugal pumps, heat exchangers, valves, instrumentation, and control systems. It operates by heating the glycol-water mixture using hot steam or engine jacket water, circulating it through centrifugal pumps, and distributing it to downstream equipment requiring thermal energy.

The Marine Glycol Heating Equipment is a specialized thermal management system designed for marine applications, particularly in LNG-powered vessels. This equipment efficiently heats glycol-water mixture to provide reliable thermal energy for various shipboard systems.

The system primarily consists of centrifugal pumps, heat exchangers, valves, instrumentation, and control systems. It operates by heating the glycol-water mixture using hot steam or engine jacket water, circulating it through centrifugal pumps, and distributing it to downstream equipment requiring thermal energy.

Functions and Features

● Dual-circuit design with one operational circuit and one standby circuit to ensure continuous operation and meet switching requirements

● Optional external electric heater installation to meet cold start requirements in various operating conditions

● Compliant with product certification requirements of major classification societies including DNV, CCS, ABS, and others

● Robust construction suitable for marine environments with high corrosion resistance

● Energy-efficient design optimizing heat transfer and circulation efficiency

● Comprehensive safety features and monitoring systems for reliable operation

Application Scenarios

The Marine Glycol Heating Equipment is primarily designed to provide heated glycol-water mixture for LNG-powered vessels and supply thermal energy for heating power media in downstream systems.

Specific applications include:

● LNG-fueled ships requiring thermal management for fuel gas supply systems

● Marine vessels utilizing glycol-based heating systems for equipment protection

● Offshore platforms and marine installations requiring reliable heating solutions

● Dual-fuel vessels operating with LNG and conventional marine fuels

● Specialized marine applications requiring precise temperature control

Functions and Features

● Dual-circuit design with one operational circuit and one standby circuit to ensure continuous operation and meet switching requirements

● Optional external electric heater installation to meet cold start requirements in various operating conditions

● Compliant with product certification requirements of major classification societies including DNV, CCS, ABS, and others

● Robust construction suitable for marine environments with high corrosion resistance

● Energy-efficient design optimizing heat transfer and circulation efficiency

● Comprehensive safety features and monitoring systems for reliable operation

Application Scenarios

The Marine Glycol Heating Equipment is primarily designed to provide heated glycol-water mixture for LNG-powered vessels and supply thermal energy for heating power media in downstream systems.

Specific applications include:

● LNG-fueled ships requiring thermal management for fuel gas supply systems

● Marine vessels utilizing glycol-based heating systems for equipment protection

● Offshore platforms and marine installations requiring reliable heating solutions

● Dual-fuel vessels operating with LNG and conventional marine fuels

● Specialized marine applications requiring precise temperature control

Marine LNG Gas Supply System-

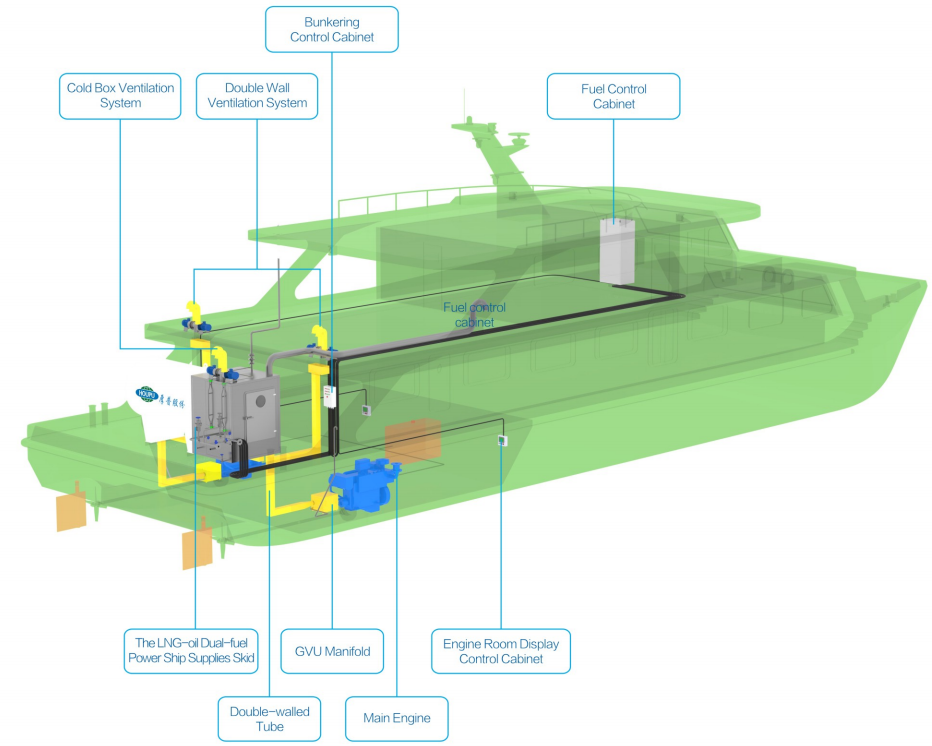

Marine LNG Gas Supply System

The Marine LNG Gas Supply System is specifically designed for LNG-fueled vessels and serves as an integrated solution for gas supply management. It enables comprehensive functions including automatic and manual gas supply, bunkering and replenishment...

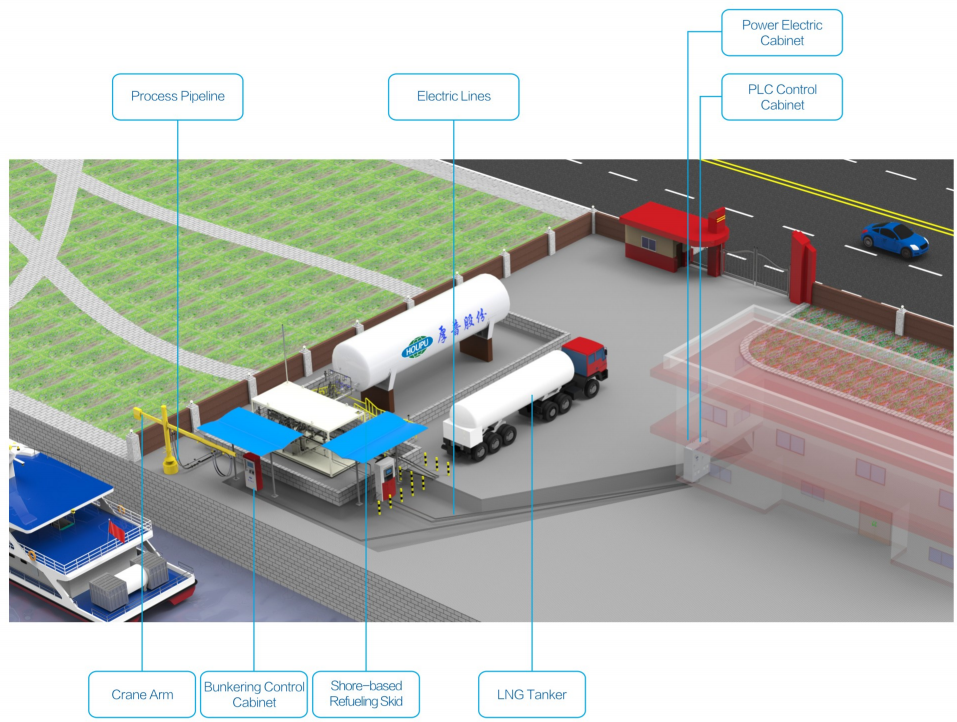

Shore-based LNG Bunkering Station Pump Skid-

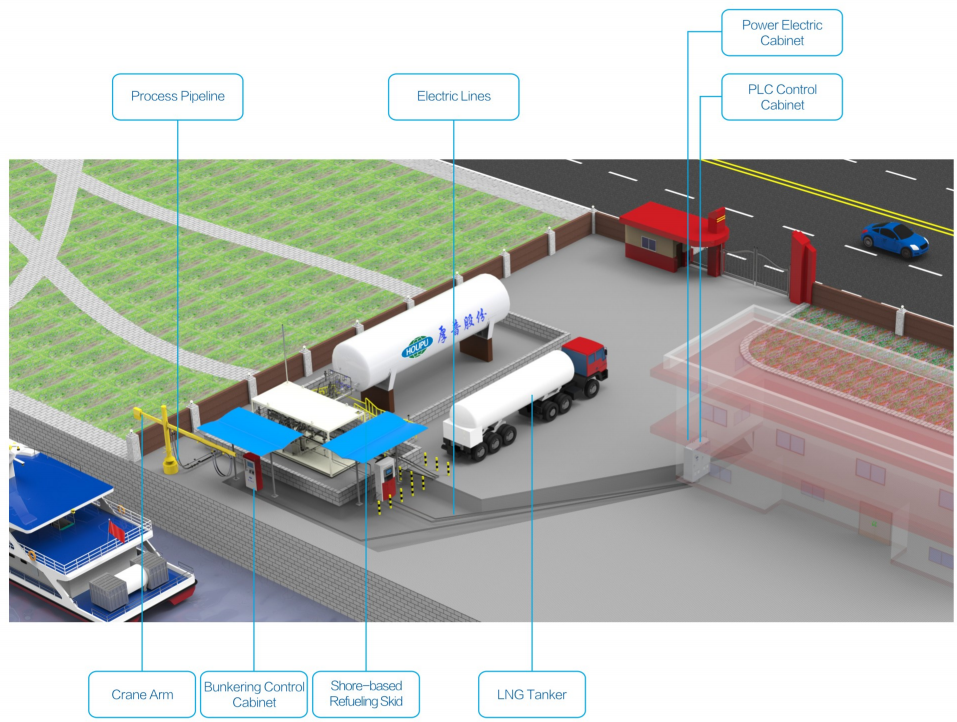

Shore-based LNG Bunkering Station Pump Skid

The shore-based LNG bunkering station is a land-based facility constructed along coastal or inland waterways. Suitable for areas with flat terrain, proximity to deep water zones, narrow channels, and environments compliant with the "Interim Provision...

Mobile LNG Bunkering Station Pump Skid-

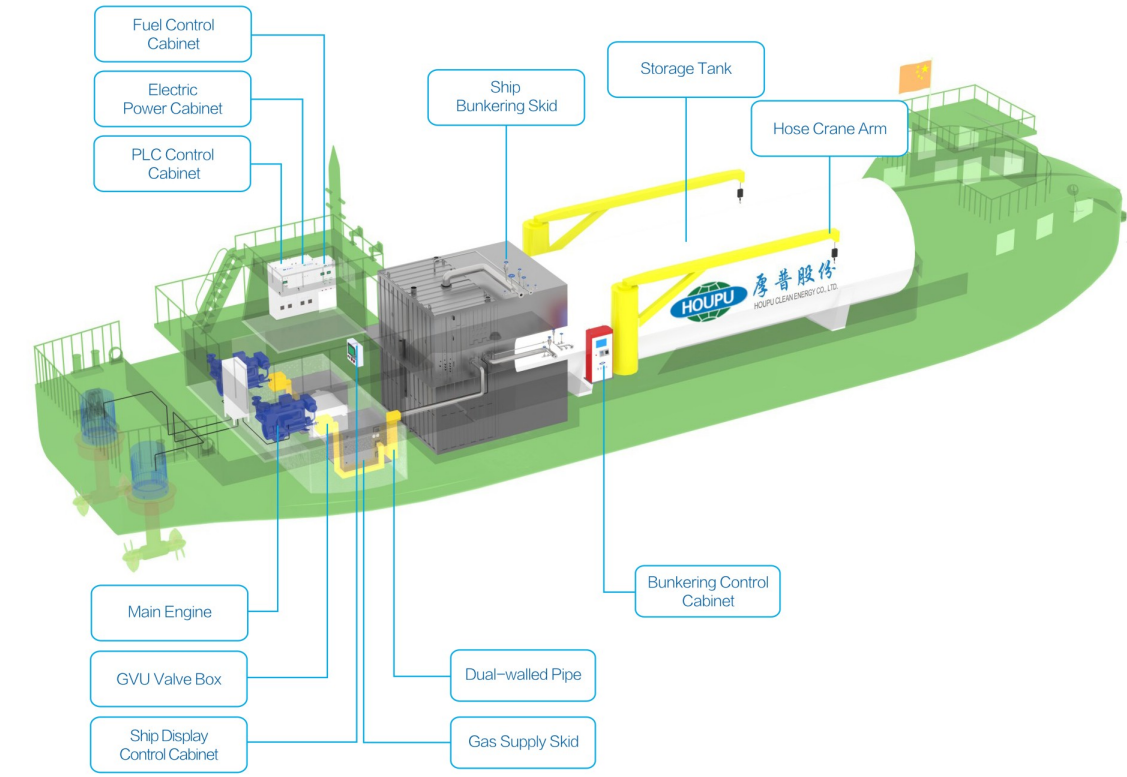

Mobile LNG Bunkering Station Pump Skid

The Mobile LNG Bunkering System is a flexible refueling solution designed to service LNG-powered vessels. With minimal requirements for water conditions, it can perform bunkering operations from various sources including shore-based stations, floatin...

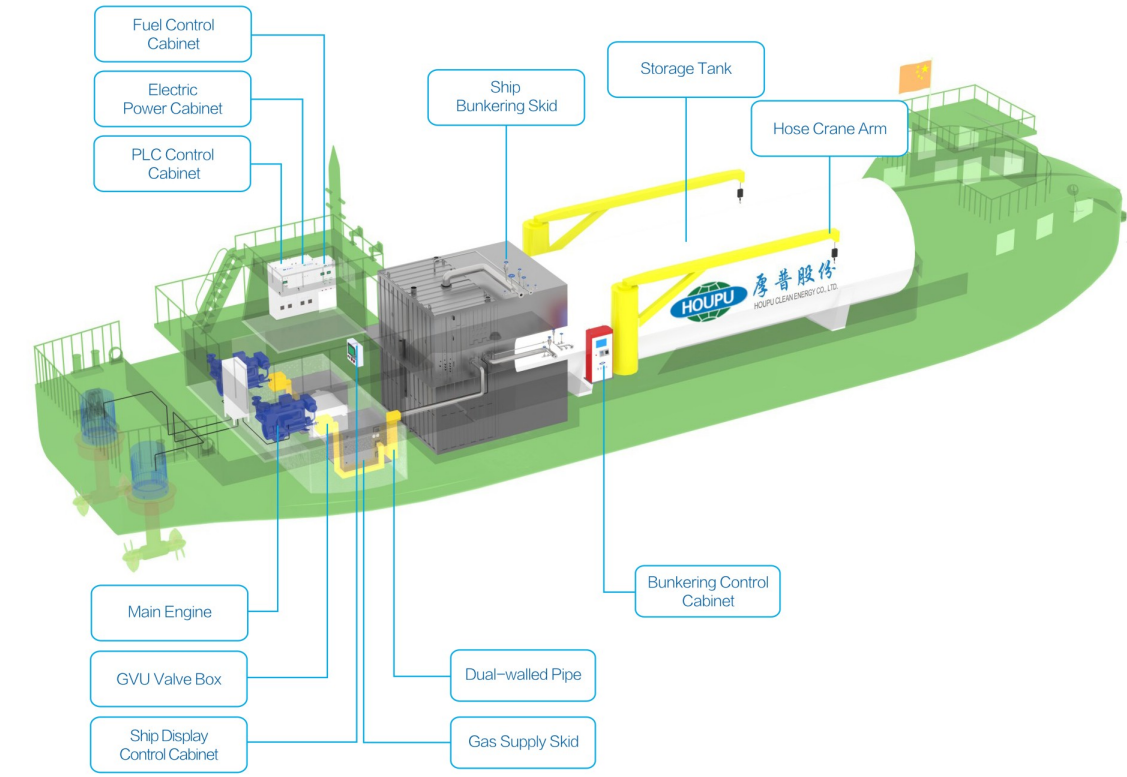

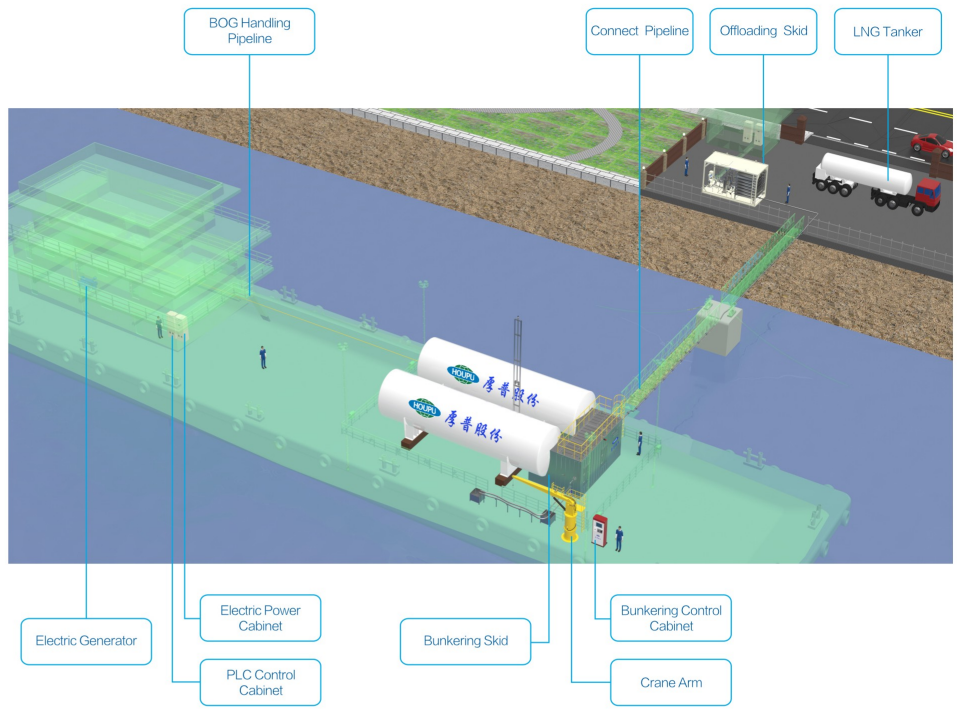

Floating LNG Bunkering Station Pump Skid-

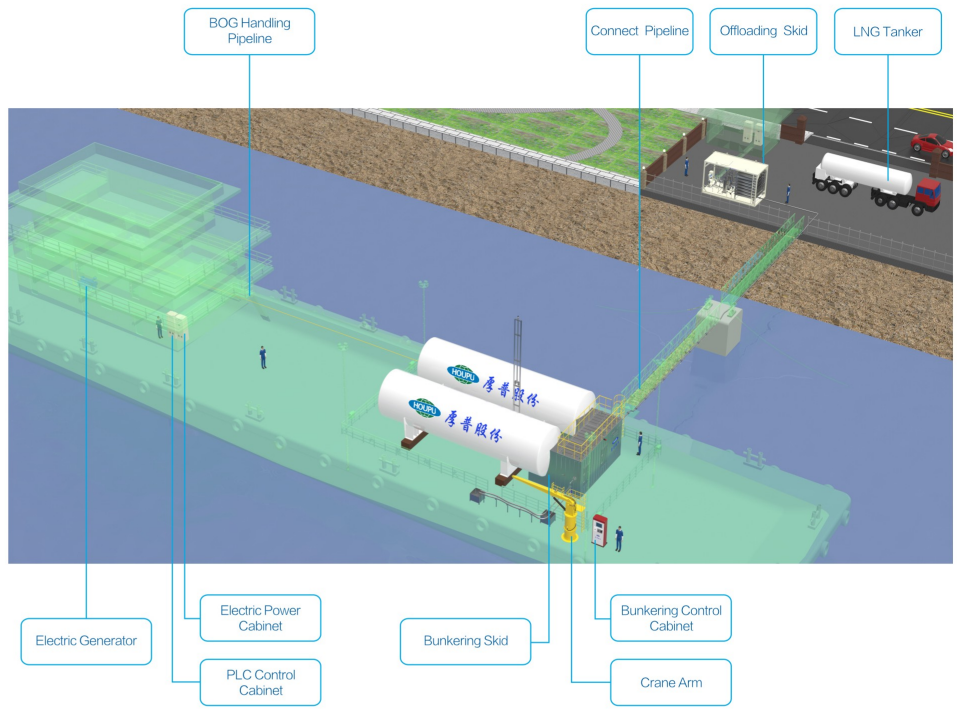

Floating LNG Bunkering Station Pump Skid

The floating ship-based LNG bunkering system is a non-self-propelled vessel equipped with complete refueling infrastructure. It is ideally deployed in sheltered waters with short shore connections, wide channels, gentle currents, deep water depths, a...

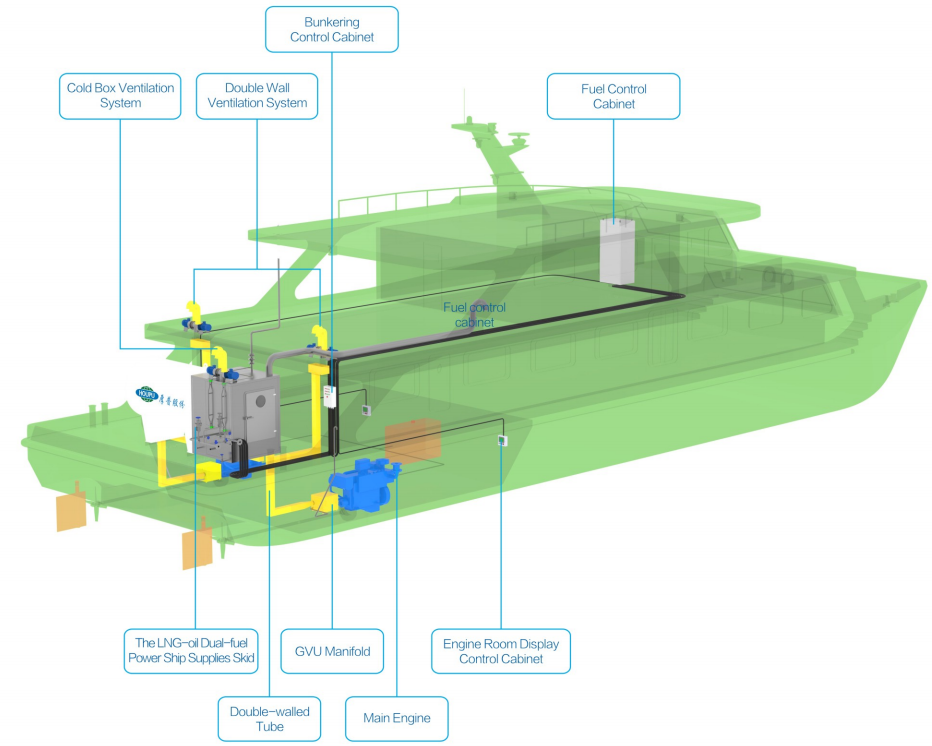

Inland River Powered Ship Gas Supply System-

Inland River Powered Ship Gas Supply System

The second-generation inland river vessel gas supply system stabilizes the natural gas produced by vaporizing LNG and supplies it to the marine gas engine to provide propulsion and auxiliary power for the vessel. Core components of the system, includ...

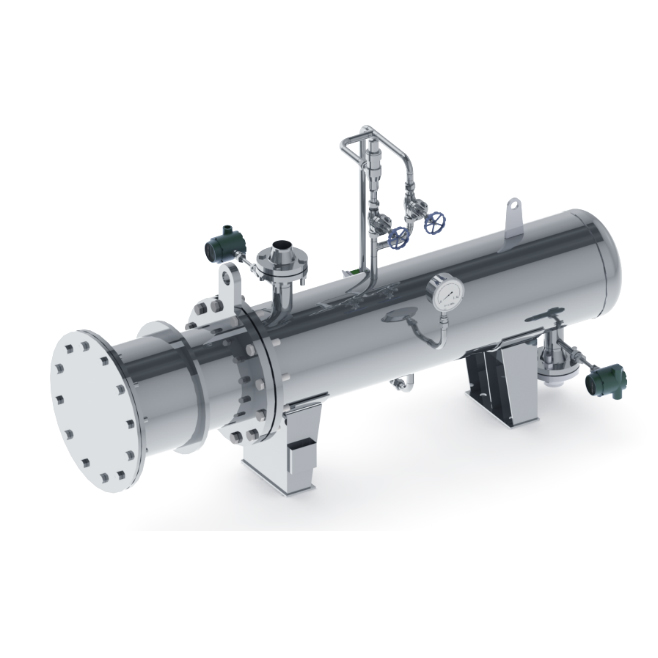

Marine Heat Exchanger-

Marine Heat Exchanger

In LNG dual-fuel powered vessels, the gas supply system for dual-fuel engines utilizes LNG as the primary fuel source. LNG is stored in cryogenic tanks or cargo tanks, then pressurized by pumps or tank booster units before being supplied to the gas d...

LNG-Powered Ship Control System-

LNG-Powered Ship Control System

This control system is designed in full compliance with the China Classification Society (CCS) "Rules for Natural Gas Fuelled Ships" (2021 Edition), specifically meeting the requirement for "separate control of fuel monitoring, control system and saf...

Marine Double-Wall Pipe System-

Marine Double-Wall Pipe System

The marine double-wall pipe system features a pipe-within-a-pipe configuration, where the inner carrier pipe is enclosed within an outer jacket pipe, creating an annular space between the two layers. This interstitial space serves as a containment ba...

Marine LNG Gas Supply System-

Marine LNG Gas Supply System

The Marine LNG Gas Supply System is specifically designed for LNG-fueled vessels and serves as an integrated solution for gas supply management. It enables comprehensive functions including automatic and manual gas supply, bunkering and replenishment...

Shore-based LNG Bunkering Station Pump Skid-

Shore-based LNG Bunkering Station Pump Skid

The shore-based LNG bunkering station is a land-based facility constructed along coastal or inland waterways. Suitable for areas with flat terrain, proximity to deep water zones, narrow channels, and environments compliant with the "Interim Provision...

Mobile LNG Bunkering Station Pump Skid-

Mobile LNG Bunkering Station Pump Skid

The Mobile LNG Bunkering System is a flexible refueling solution designed to service LNG-powered vessels. With minimal requirements for water conditions, it can perform bunkering operations from various sources including shore-based stations, floatin...

Floating LNG Bunkering Station Pump Skid-

Floating LNG Bunkering Station Pump Skid

The floating ship-based LNG bunkering system is a non-self-propelled vessel equipped with complete refueling infrastructure. It is ideally deployed in sheltered waters with short shore connections, wide channels, gentle currents, deep water depths, a...

Inland River Powered Ship Gas Supply System-

Inland River Powered Ship Gas Supply System

The second-generation inland river vessel gas supply system stabilizes the natural gas produced by vaporizing LNG and supplies it to the marine gas engine to provide propulsion and auxiliary power for the vessel. Core components of the system, includ...

Marine Heat Exchanger-

Marine Heat Exchanger

In LNG dual-fuel powered vessels, the gas supply system for dual-fuel engines utilizes LNG as the primary fuel source. LNG is stored in cryogenic tanks or cargo tanks, then pressurized by pumps or tank booster units before being supplied to the gas d...

LNG-Powered Ship Control System-

LNG-Powered Ship Control System

This control system is designed in full compliance with the China Classification Society (CCS) "Rules for Natural Gas Fuelled Ships" (2021 Edition), specifically meeting the requirement for "separate control of fuel monitoring, control system and saf...

Marine Double-Wall Pipe System-

Marine Double-Wall Pipe System

The marine double-wall pipe system features a pipe-within-a-pipe configuration, where the inner carrier pipe is enclosed within an outer jacket pipe, creating an annular space between the two layers. This interstitial space serves as a containment ba...