Vehicle Application

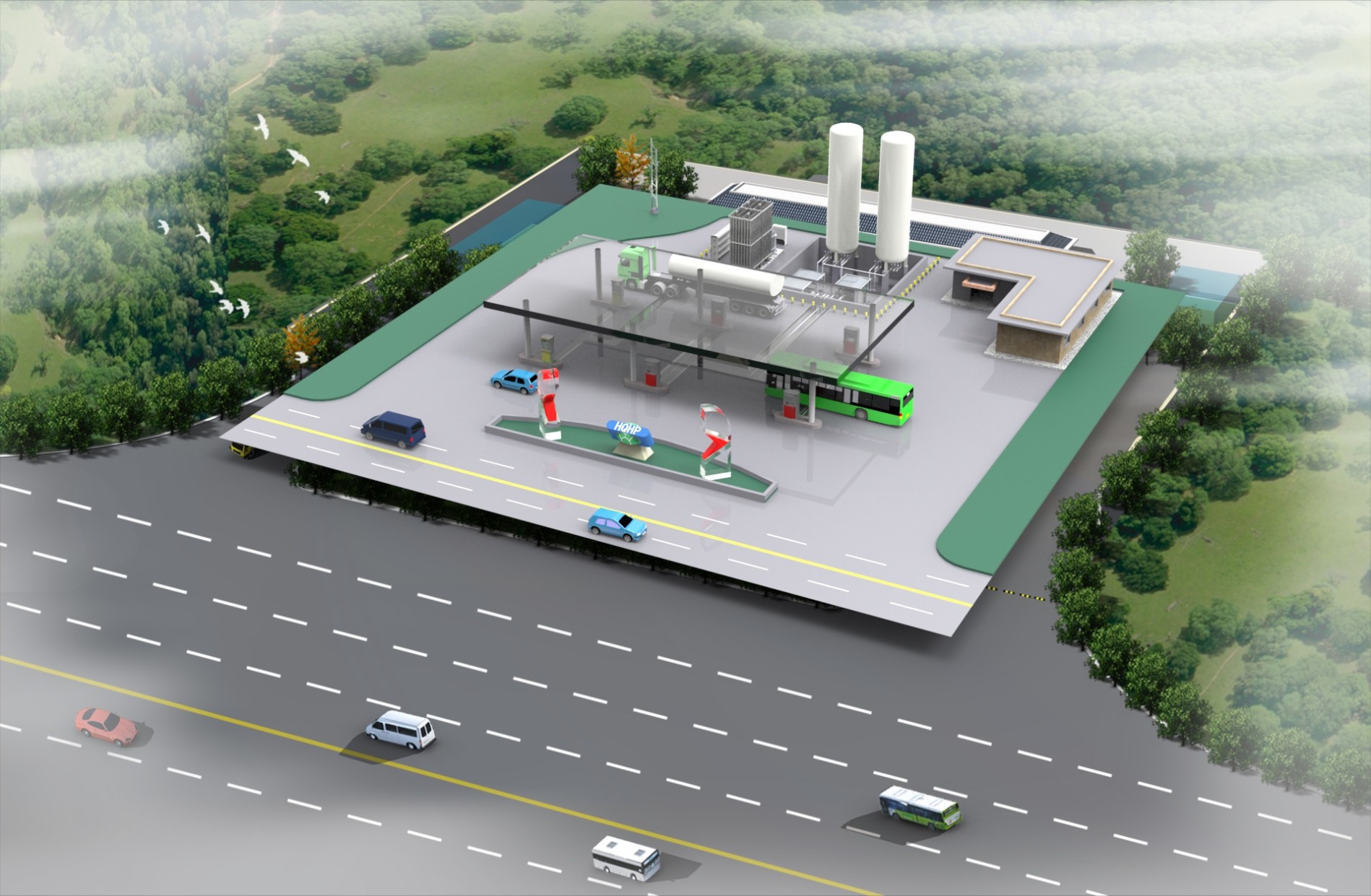

Containerized L-CNG Refueling Station

The L-CNG skid-mounted refueling station integrates the storage tank, plunger pump, unloading system, and pressurization system within a containerized skid structure featuring a metal cofferdam. Only the HP vaporizer skid, CNG storage cylinders, instrument air system, and control system are installed externally.

The L-CNG skid-mounted refueling station integrates the storage tank, plunger pump, unloading system, and pressurization system within a containerized skid structure featuring a metal cofferdam. Only the HP vaporizer skid, CNG storage cylinders, instrument air system, and control system are installed externally.

Product Advantages

· High Integration: Integrates core functional modules including LNG storage, pressurization, vaporization, and control within a standard container, significantly reducing footprint and on-site installation work.

· Quick Deployment: Utilizes prefabricated modular design, requiring only simple connection and commissioning on-site before operation. Project construction cycle is reduced by over 60% compared to traditional stations.

· Economical Efficiency: Compared to traditional CNG mother stations, using LNG as feedstock gas can reduce operating costs by 20-30%, while also reducing equipment investment and land occupation.

· Safety & Reliability: Equipped with multiple safety protection systems, compliant with international safety standards, ensuring stable operation and personnel/equipment safety under various working conditions.

· Intelligent Control: Utilizes advanced PLC control system for fully automatic operation, remote monitoring, and fault diagnosis, reducing manual intervention and improving operational efficiency.

· Flexible Expansion: Modular design supports flexible adjustment of configuration and capacity according to requirements, facilitating later expansion and functional upgrades to adapt to different scale application scenarios.

Application Scenarios

· Urban Transportation: CNG refueling for buses and taxis

· Logistics Transportation: CNG fuel supply for freight vehicles

· Industrial Parks: Gas supply for industrial enterprises

· Remote Areas: Gas supply for regions without pipeline natural gas

· Emergency Gas Supply: Temporary or emergency gas supply

· Oil & Gas Fields: Utilization of associated gas from oil fields

Optional Configurations

· Remote Monitoring System

· Data Analysis Platform

· Vehicle Identification System

· Online Payment System

· BOG Recovery System

· Dual Power Supply System

Product Advantages

· High Integration: Integrates core functional modules including LNG storage, pressurization, vaporization, and control within a standard container, significantly reducing footprint and on-site installation work.

· Quick Deployment: Utilizes prefabricated modular design, requiring only simple connection and commissioning on-site before operation. Project construction cycle is reduced by over 60% compared to traditional stations.

· Economical Efficiency: Compared to traditional CNG mother stations, using LNG as feedstock gas can reduce operating costs by 20-30%, while also reducing equipment investment and land occupation.

· Safety & Reliability: Equipped with multiple safety protection systems, compliant with international safety standards, ensuring stable operation and personnel/equipment safety under various working conditions.

· Intelligent Control: Utilizes advanced PLC control system for fully automatic operation, remote monitoring, and fault diagnosis, reducing manual intervention and improving operational efficiency.

· Flexible Expansion: Modular design supports flexible adjustment of configuration and capacity according to requirements, facilitating later expansion and functional upgrades to adapt to different scale application scenarios.

Application Scenarios

· Urban Transportation: CNG refueling for buses and taxis

· Logistics Transportation: CNG fuel supply for freight vehicles

· Industrial Parks: Gas supply for industrial enterprises

· Remote Areas: Gas supply for regions without pipeline natural gas

· Emergency Gas Supply: Temporary or emergency gas supply

· Oil & Gas Fields: Utilization of associated gas from oil fields

Optional Configurations

· Remote Monitoring System

· Data Analysis Platform

· Vehicle Identification System

· Online Payment System

· BOG Recovery System

· Dual Power Supply System

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

PLC Control Cabinet for CNG Station-

PLC Control Cabinet for CNG Station

The Program Control Panel is an automated control device used in the gas storage systems (cylinders, tanks, wells) of CNG refueling stations. It implements an energy-saving gas storage method by sequentially supplying gas to the storage system in gro...

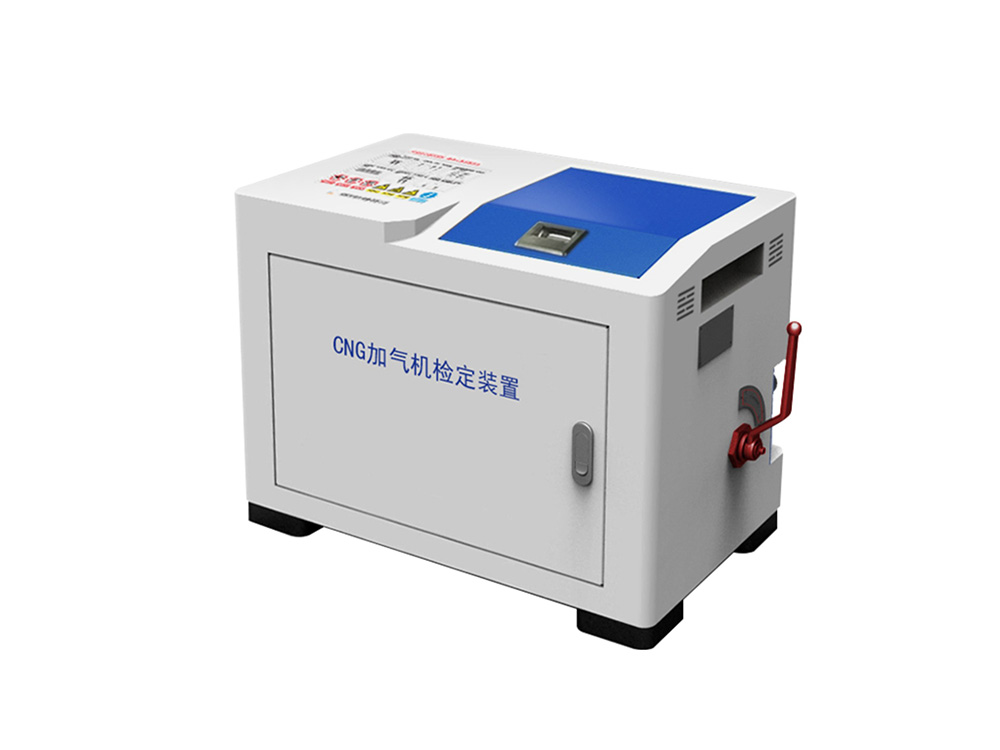

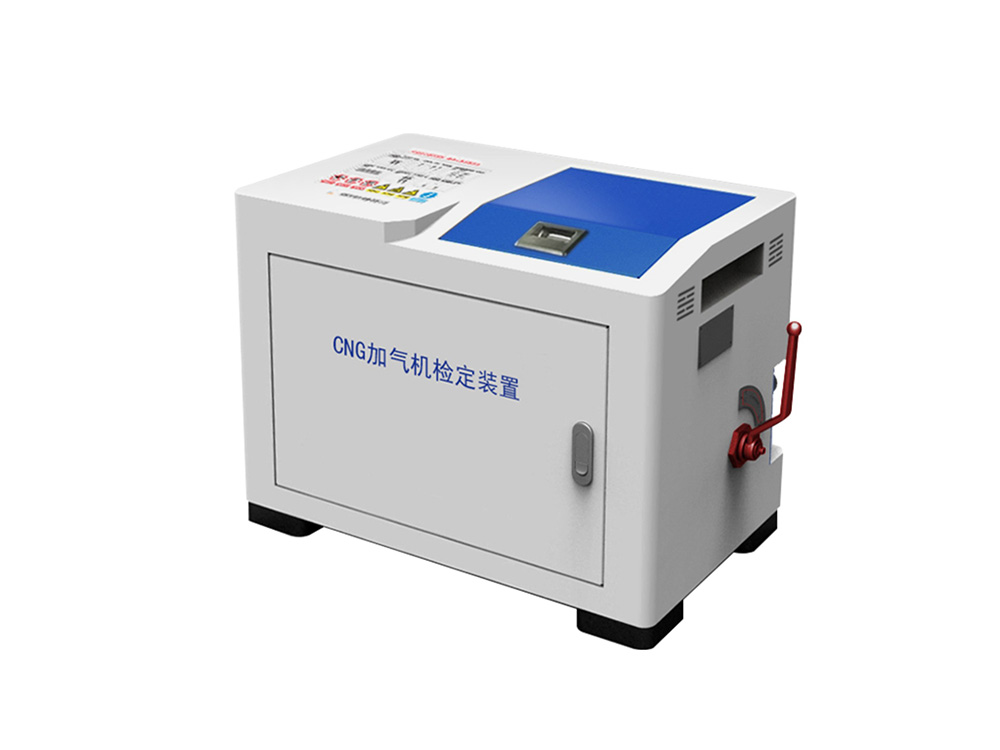

LNG Dispenser Calibrator-

LNG Dispenser Calibrator

The LNG Dispenser Calibrator is a professional instrument designed for the verification and calibration of LNG dispensers. It provides comprehensive functionalities including real-time data acquisition during inspection, detailed query of verificatio...

LNG Refueling Station Control System-

LNG Refueling Station Control System

This LNG station control system, developed under the National 863 Program project, utilizes a robust architecture based on PLC and SCADA technologies. It provides comprehensive monitoring and control of all equipment within the LNG refueling station,...

LNG Single/Double Pump Skid-

LNG Single/Double Pump Skid

The LNG Single/Double Pump Skid is designed for transferring LNG from tanker trailers to on-site storage tanks. It primarily consists of a cryogenic submerged pump, a cryogenic vacuum pump, a vaporizer, cryogenic valves, a piping system, pressure sen...

Unmanned Containerized LNG Refueling Station-

Unmanned Containerized LNG Refueling Station

The containerized filling skid is an integrated equipment system that incorporates LNG storage tanks, cryogenic submerged pumps, vaporizers, liquid filling control cabinets, and other components within a containerized skid structure (featuring metal-...

Containerized LNG Refueling Station-

Containerized LNG Refueling Station

HOUPU's containerized LNG refueling station adopts a modular design, standardized management, and intelligent production concepts. It is characterized by an aesthetically pleasing appearance, stable performance, reliable quality, and high refueling e...

Double Pump LCNG Refueling Skid-

Double Pump LCNG Refueling Skid

The Double Pump LCNG Refueling Skid adopts a modular design approach, incorporating standardized management and intelligent production concepts. This integrated system combines the advantages of both LNG and CNG refueling technologies in a single, ef...

L-CNG/CNG Refueling Station-

L-CNG/CNG Refueling Station

The system utilizes a cryogenic high-pressure plunger pump to pressurize LNG to 20-25 MPa. The high-pressure liquid then enters a high-pressure air-cooled vaporizer, where it is converted into Compressed Natural Gas (CNG). Finally, the CNG is dispens...

LNG Refueling Station-

LNG Refueling Station

LNG refueling stations are available in two primary configurations: the Pump Skid and the Permanent Station. ● Permanent Refueling Station: All equipment is fixed and installed on-site at the station location. ● Pump Skid: All key equipment is in...

LNG Dispenser-

LNG Dispenser

The HOUPU LNG Multi-Purpose Intelligent Dispenser integrates a high-accuracy mass flow meter, LNG refueling nozzle, breakaway coupling, ESD system, and a self-developed microprocessor control system. It serves as a gas metering device for trade settl...

CNG Dispenser-

CNG Dispenser

The CNG General-Purpose Dispenser provides an efficient solution for delivering compressed natural gas (CNG) to NGV vehicles. Primarily used in CNG stations for metering and trade settlement, it eliminates the need for a separate POS system. The disp...

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

PLC Control Cabinet for CNG Station-

PLC Control Cabinet for CNG Station

The Program Control Panel is an automated control device used in the gas storage systems (cylinders, tanks, wells) of CNG refueling stations. It implements an energy-saving gas storage method by sequentially supplying gas to the storage system in gro...

LNG Dispenser Calibrator-

LNG Dispenser Calibrator

The LNG Dispenser Calibrator is a professional instrument designed for the verification and calibration of LNG dispensers. It provides comprehensive functionalities including real-time data acquisition during inspection, detailed query of verificatio...

LNG Refueling Station Control System-

LNG Refueling Station Control System

This LNG station control system, developed under the National 863 Program project, utilizes a robust architecture based on PLC and SCADA technologies. It provides comprehensive monitoring and control of all equipment within the LNG refueling station,...

LNG Single/Double Pump Skid-

LNG Single/Double Pump Skid

The LNG Single/Double Pump Skid is designed for transferring LNG from tanker trailers to on-site storage tanks. It primarily consists of a cryogenic submerged pump, a cryogenic vacuum pump, a vaporizer, cryogenic valves, a piping system, pressure sen...

Unmanned Containerized LNG Refueling Station-

Unmanned Containerized LNG Refueling Station

The containerized filling skid is an integrated equipment system that incorporates LNG storage tanks, cryogenic submerged pumps, vaporizers, liquid filling control cabinets, and other components within a containerized skid structure (featuring metal-...

Containerized LNG Refueling Station-

Containerized LNG Refueling Station

HOUPU's containerized LNG refueling station adopts a modular design, standardized management, and intelligent production concepts. It is characterized by an aesthetically pleasing appearance, stable performance, reliable quality, and high refueling e...

Double Pump LCNG Refueling Skid-

Double Pump LCNG Refueling Skid

The Double Pump LCNG Refueling Skid adopts a modular design approach, incorporating standardized management and intelligent production concepts. This integrated system combines the advantages of both LNG and CNG refueling technologies in a single, ef...