Vehicle Application

Containerized LNG Refueling Station

HOUPU's containerized LNG refueling station adopts a modular design, standardized management, and intelligent production concepts. It is characterized by an aesthetically pleasing appearance, stable performance, reliable quality, and high refueling efficiency.

Compared to permanent LNG stations, the containerized type offers advantages such as a smaller footprint, less civil work, and easier transportation. It is suitable for users with space constraints and those who require rapid deployment.

The station is primarily composed of an LNG dispenser, LNG vaporizer, and LNG storage tank. The number of dispensers, tank size, and other detailed configurations can be customized according to requirements.

The main components include standard containers, stainless steel metal cofferdams, vacuum storage tanks, cryogenic submerged pumps, cryogenic vacuum pumps, vaporizers, cryogenic valves, pressure sensors, temperature sensors, gas detectors, emergency stop buttons, dispensers, and the piping system.

HOUPU's containerized LNG refueling station adopts a modular design, standardized management, and intelligent production concepts. It is characterized by an aesthetically pleasing appearance, stable performance, reliable quality, and high refueling efficiency.

Compared to permanent LNG stations, the containerized type offers advantages such as a smaller footprint, less civil work, and easier transportation. It is suitable for users with space constraints and those who require rapid deployment.

The station is primarily composed of an LNG dispenser, LNG vaporizer, and LNG storage tank. The number of dispensers, tank size, and other detailed configurations can be customized according to requirements.

The main components include standard containers, stainless steel metal cofferdams, vacuum storage tanks, cryogenic submerged pumps, cryogenic vacuum pumps, vaporizers, cryogenic valves, pressure sensors, temperature sensors, gas detectors, emergency stop buttons, dispensers, and the piping system.

Product Features

● Comprehensive safety protection design, compliant with GB/CE standards.

● Fast on-site installation and commissioning, featuring a plug-and-play design that is ready for relocation.

● Sound quality management system ensuring reliable product quality and long service life.

● Utilization of double-walled stainless steel high-vacuum pipelines, resulting in short pre-cooling time and fast filling speed.

● Standard 85L high-vacuum pump sump, compatible with internationally renowned cryogenic submerged pump brands.

● Dedicated frequency converter for automatic filling pressure adjustment, contributing to energy savings and reduced carbon emissions.

● Equipped with an independent pressurizing vaporizer and an EAG vaporizer, both offering high vaporization efficiency.

● Configuration includes a dedicated instrument panel for monitoring pressure, liquid level, temperature, and other parameters.

● Supports the configuration of multiple dispensers (up to 4 units).

● Integrates multiple functions including LNG refueling, unloading, pressure regulation, and safe release.

● Optional liquid nitrogen (LIN) cooling system and inline saturator (SOF) system are available.

● Standardized assembly line production with an annual output exceeding 100 units.

Application Scenarios

This product is designed for LNG refueling stations with a daily filling capacity of approximately 50 m³.

Product Features

● Comprehensive safety protection design, compliant with GB/CE standards.

● Fast on-site installation and commissioning, featuring a plug-and-play design that is ready for relocation.

● Sound quality management system ensuring reliable product quality and long service life.

● Utilization of double-walled stainless steel high-vacuum pipelines, resulting in short pre-cooling time and fast filling speed.

● Standard 85L high-vacuum pump sump, compatible with internationally renowned cryogenic submerged pump brands.

● Dedicated frequency converter for automatic filling pressure adjustment, contributing to energy savings and reduced carbon emissions.

● Equipped with an independent pressurizing vaporizer and an EAG vaporizer, both offering high vaporization efficiency.

● Configuration includes a dedicated instrument panel for monitoring pressure, liquid level, temperature, and other parameters.

● Supports the configuration of multiple dispensers (up to 4 units).

● Integrates multiple functions including LNG refueling, unloading, pressure regulation, and safe release.

● Optional liquid nitrogen (LIN) cooling system and inline saturator (SOF) system are available.

● Standardized assembly line production with an annual output exceeding 100 units.

Application Scenarios

This product is designed for LNG refueling stations with a daily filling capacity of approximately 50 m³.

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

PLC Control Cabinet for CNG Station-

PLC Control Cabinet for CNG Station

The Program Control Panel is an automated control device used in the gas storage systems (cylinders, tanks, wells) of CNG refueling stations. It implements an energy-saving gas storage method by sequentially supplying gas to the storage system in gro...

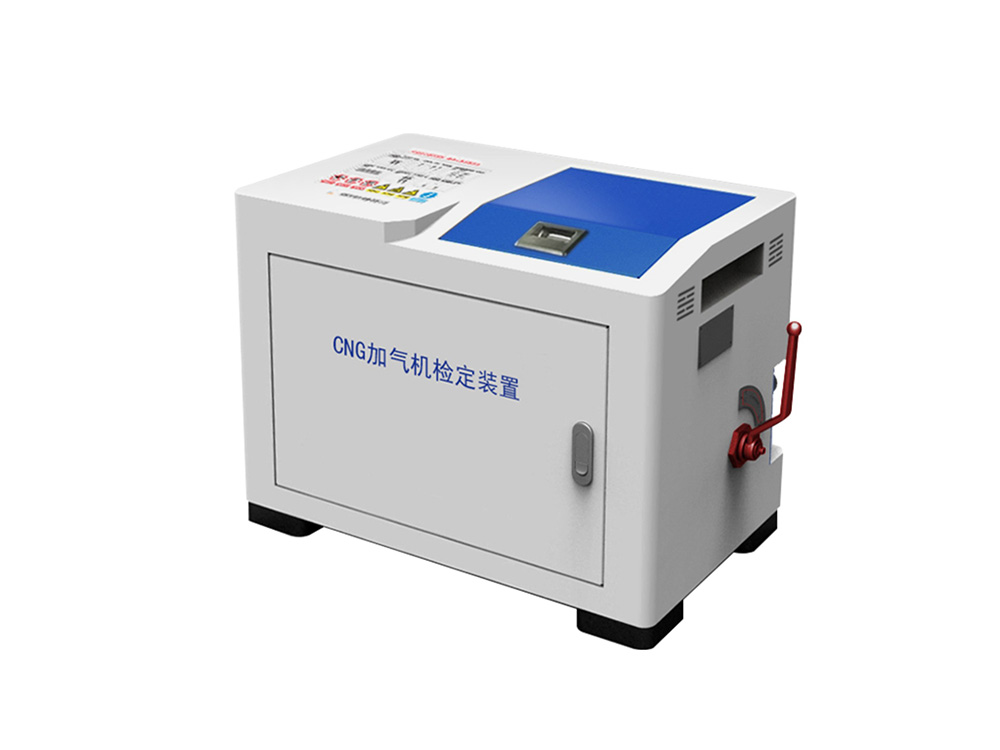

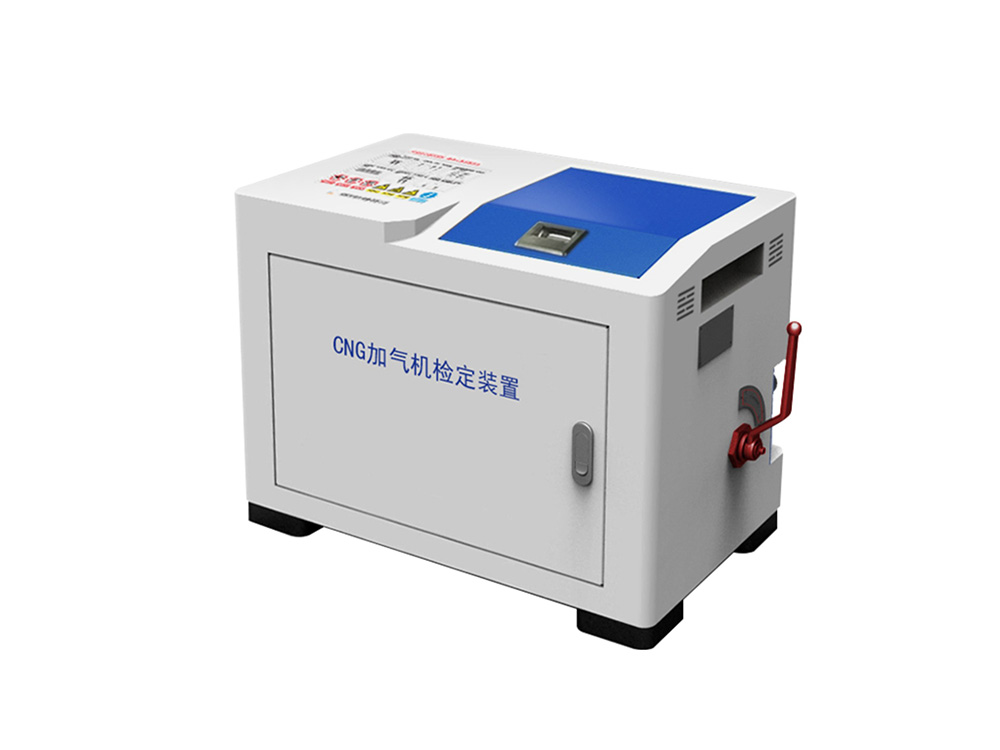

LNG Dispenser Calibrator-

LNG Dispenser Calibrator

The LNG Dispenser Calibrator is a professional instrument designed for the verification and calibration of LNG dispensers. It provides comprehensive functionalities including real-time data acquisition during inspection, detailed query of verificatio...

LNG Refueling Station Control System-

LNG Refueling Station Control System

This LNG station control system, developed under the National 863 Program project, utilizes a robust architecture based on PLC and SCADA technologies. It provides comprehensive monitoring and control of all equipment within the LNG refueling station,...

LNG Single/Double Pump Skid-

LNG Single/Double Pump Skid

The LNG Single/Double Pump Skid is designed for transferring LNG from tanker trailers to on-site storage tanks. It primarily consists of a cryogenic submerged pump, a cryogenic vacuum pump, a vaporizer, cryogenic valves, a piping system, pressure sen...

Unmanned Containerized LNG Refueling Station-

Unmanned Containerized LNG Refueling Station

The containerized filling skid is an integrated equipment system that incorporates LNG storage tanks, cryogenic submerged pumps, vaporizers, liquid filling control cabinets, and other components within a containerized skid structure (featuring metal-...

Double Pump LCNG Refueling Skid-

Double Pump LCNG Refueling Skid

The Double Pump LCNG Refueling Skid adopts a modular design approach, incorporating standardized management and intelligent production concepts. This integrated system combines the advantages of both LNG and CNG refueling technologies in a single, ef...

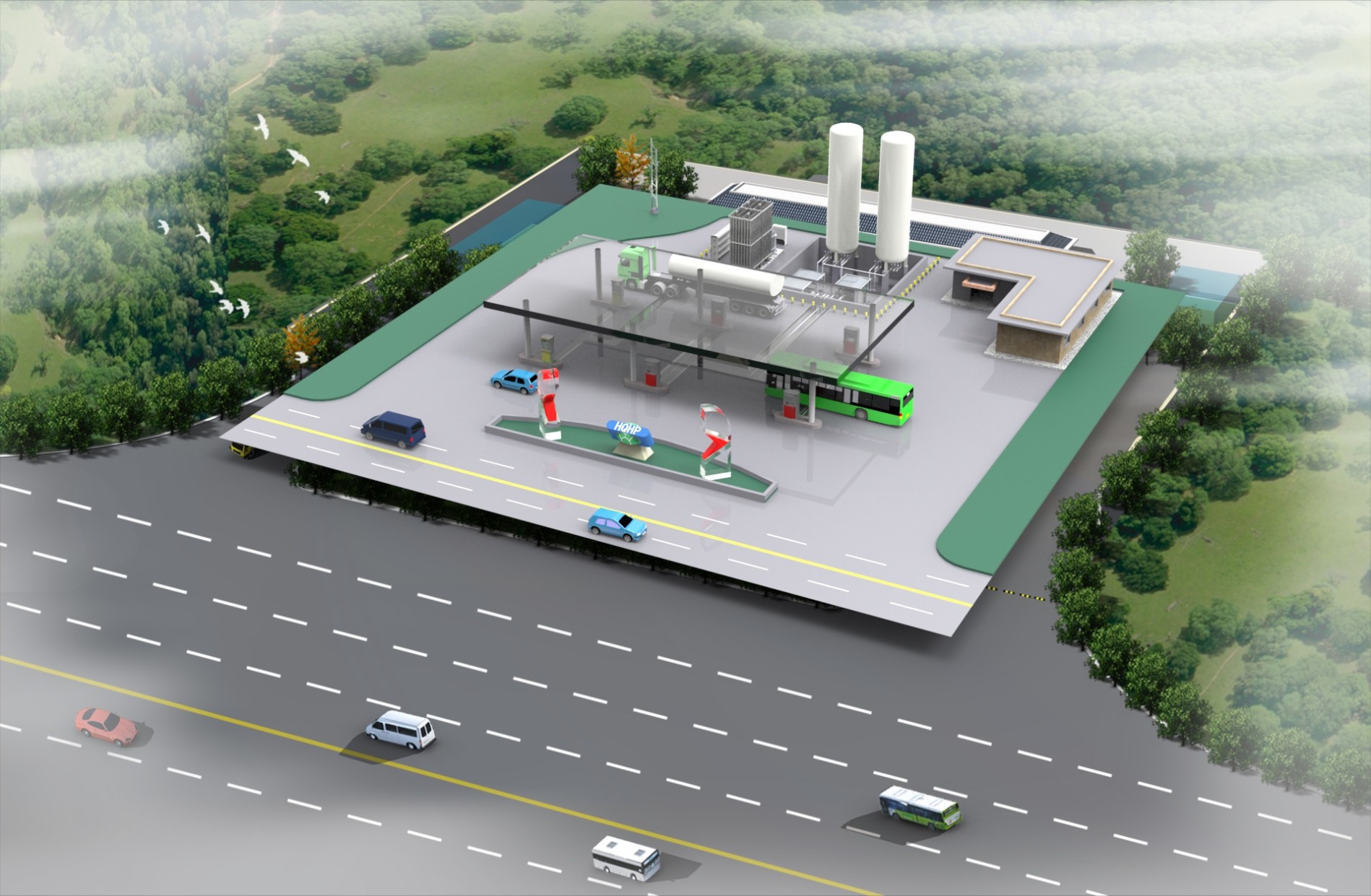

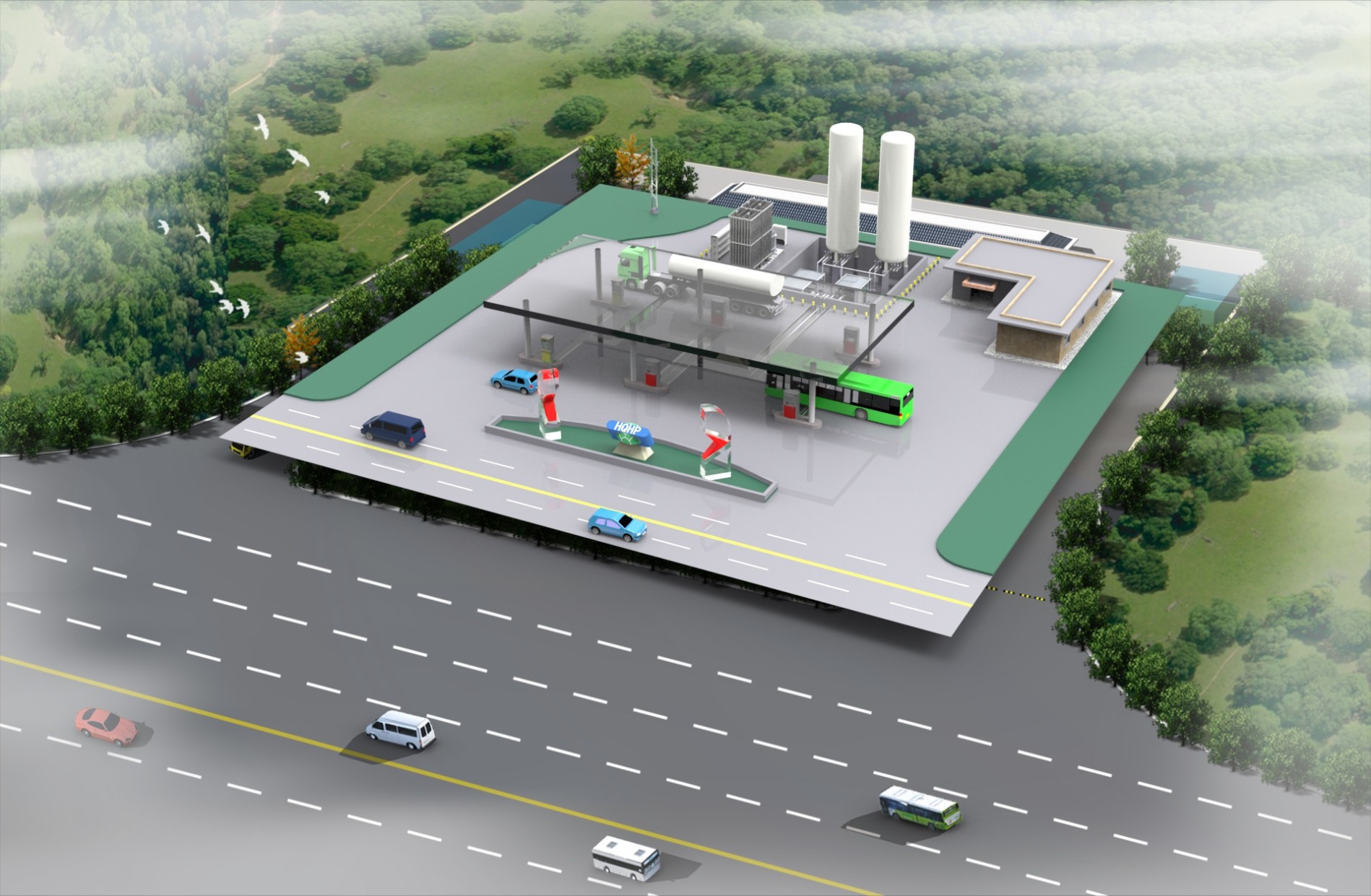

L-CNG/CNG Refueling Station-

L-CNG/CNG Refueling Station

The system utilizes a cryogenic high-pressure plunger pump to pressurize LNG to 20-25 MPa. The high-pressure liquid then enters a high-pressure air-cooled vaporizer, where it is converted into Compressed Natural Gas (CNG). Finally, the CNG is dispens...

LNG Refueling Station-

LNG Refueling Station

LNG refueling stations are available in two primary configurations: the Pump Skid and the Permanent Station. ● Permanent Refueling Station: All equipment is fixed and installed on-site at the station location. ● Pump Skid: All key equipment is in...

LNG Dispenser-

LNG Dispenser

The HOUPU LNG Multi-Purpose Intelligent Dispenser integrates a high-accuracy mass flow meter, LNG refueling nozzle, breakaway coupling, ESD system, and a self-developed microprocessor control system. It serves as a gas metering device for trade settl...

Containerized L-CNG Refueling Station-

Containerized L-CNG Refueling Station

The L-CNG skid-mounted refueling station integrates the storage tank, plunger pump, unloading system, and pressurization system within a containerized skid structure featuring a metal cofferdam. Only the HP vaporizer skid, CNG storage cylinders, inst...

CNG Dispenser-

CNG Dispenser

The CNG General-Purpose Dispenser provides an efficient solution for delivering compressed natural gas (CNG) to NGV vehicles. Primarily used in CNG stations for metering and trade settlement, it eliminates the need for a separate POS system. The disp...

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

CNG Refueling Station Control System-

CNG Refueling Station Control System

The station-level management system is a software platform installed on a central computer. It collects real-time refueling data from all dispensers via a bus connection, securely stores this information in a dedicated database, and provides comprehe...

PLC Control Cabinet for CNG Station-

PLC Control Cabinet for CNG Station

The Program Control Panel is an automated control device used in the gas storage systems (cylinders, tanks, wells) of CNG refueling stations. It implements an energy-saving gas storage method by sequentially supplying gas to the storage system in gro...

LNG Dispenser Calibrator-

LNG Dispenser Calibrator

The LNG Dispenser Calibrator is a professional instrument designed for the verification and calibration of LNG dispensers. It provides comprehensive functionalities including real-time data acquisition during inspection, detailed query of verificatio...

LNG Refueling Station Control System-

LNG Refueling Station Control System

This LNG station control system, developed under the National 863 Program project, utilizes a robust architecture based on PLC and SCADA technologies. It provides comprehensive monitoring and control of all equipment within the LNG refueling station,...

LNG Single/Double Pump Skid-

LNG Single/Double Pump Skid

The LNG Single/Double Pump Skid is designed for transferring LNG from tanker trailers to on-site storage tanks. It primarily consists of a cryogenic submerged pump, a cryogenic vacuum pump, a vaporizer, cryogenic valves, a piping system, pressure sen...

Unmanned Containerized LNG Refueling Station-

Unmanned Containerized LNG Refueling Station

The containerized filling skid is an integrated equipment system that incorporates LNG storage tanks, cryogenic submerged pumps, vaporizers, liquid filling control cabinets, and other components within a containerized skid structure (featuring metal-...

Double Pump LCNG Refueling Skid-

Double Pump LCNG Refueling Skid

The Double Pump LCNG Refueling Skid adopts a modular design approach, incorporating standardized management and intelligent production concepts. This integrated system combines the advantages of both LNG and CNG refueling technologies in a single, ef...

L-CNG/CNG Refueling Station-

L-CNG/CNG Refueling Station

The system utilizes a cryogenic high-pressure plunger pump to pressurize LNG to 20-25 MPa. The high-pressure liquid then enters a high-pressure air-cooled vaporizer, where it is converted into Compressed Natural Gas (CNG). Finally, the CNG is dispens...